As known to many of us, 3D printing technology is widely used by many industries and will continue doing for the commercial enhancement. Airbus Group which is the largest aviation firm in Europe declares its collaboration with Dassault Systems. The association, Dassault Systems is viewed as a dominant in 3D design software and the 3DEXPERIENCE will soon shift to the Airbus additive manufacturing programs. Now, the 3D design software will enable Airbus to model the part of aircraft for its commercial use digitally.

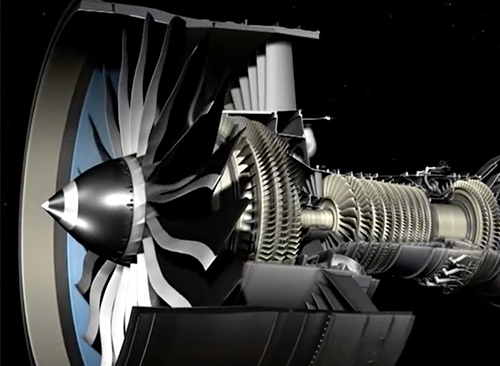

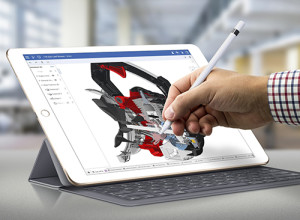

The company Airbus Group, which is a solid combination of Airbus, Airbus Defense, Space and Airbus Helicopters, incorporates 3DEXPERIENCE to its division of additive manufacturing, finally after a consistent success of two-year production process. Based on the slated information, the 3D platform functions by integrating design, simulation, and production to a product lifecycle management system (PLM) solution. The platform will come into existence by the Airbus Group for making a collaborative design, prototyping, simulate application for the additive manufacturing process, among the parts of test flights and within the production use on commercial aircraft.

However, the only problem linked to additive manufacturing is the low cost which gives a scope of errors when compared with traditional manufacturing processes. Hence, Airbus floats a solution “Co-Design to Target” for optimization of conceptual design by validation at each phase including designing of parts, production, and testing during the process. The initiative taken for optimization at each stage will ultimately contribute to the reduction of cost of manufacturing and unnecessary waste.

Moreover, additive manufacturing remains as the world best aerospace engineering firm for both the prototypes as well as finished products and a robust software solution continuing as high demand. Thus, Dassault Systems is duly interest to lend their manufacturing solution to the best among the aerospace industry. In addition to it, the idea of additive manufacture of metal parts gets further credibility when it declares the Airbus Subsidiary. Along with the 3DEXPERIENCE platform as its benchmark, they provide a variety of platforms to its industrial partners.

Robert Nardini as the Senior Vice President of Engineering Airframe at Airbus explains that “There are some projects which are increasing the use of additive manufacturing for production of prototypes as well as production components and delivering light and affordable parts that can meet the performance standards. Now, there will be a similar analysis to view the technology from every aspect if the reader is a manufacturer. Closing down the statement for Additive manufacturing, it holds a fast and energy efficient way to manufacture products without causing much wastage of material.

Image courtesy: www.newhdwallpaper.in || www.onshape.com ||

www.forwardgeek.com || www.alabamanewscenter.com || www.netc.ac.th ||

3dprintingindustry.com || www.airbus.com || autodesk.typepad.com ||