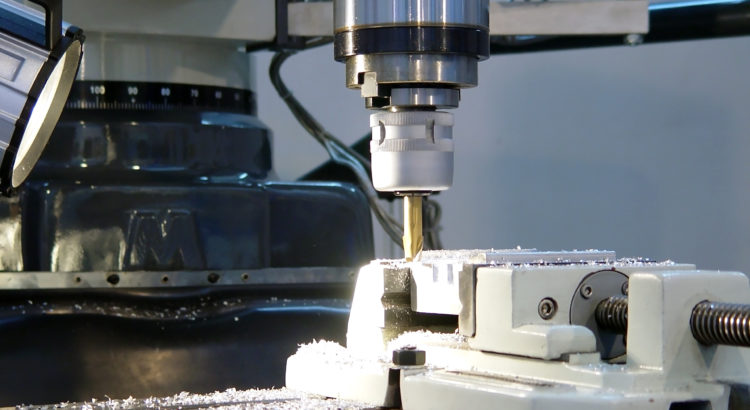

Digitalization has revolutionized the entire manufacturing sector. The labor-intensive industry has transformed into a technology-driven industry. Technology such as 3-D printing, CNC machining, industrial internet of things (IIoT), and artificial intelligence (AI) have optimized the manufacturing operations and have considerably reduced the production and maintenance cost. The details of this technological impact on manufacturing are listed below:

- Economically Viable Mass Customization

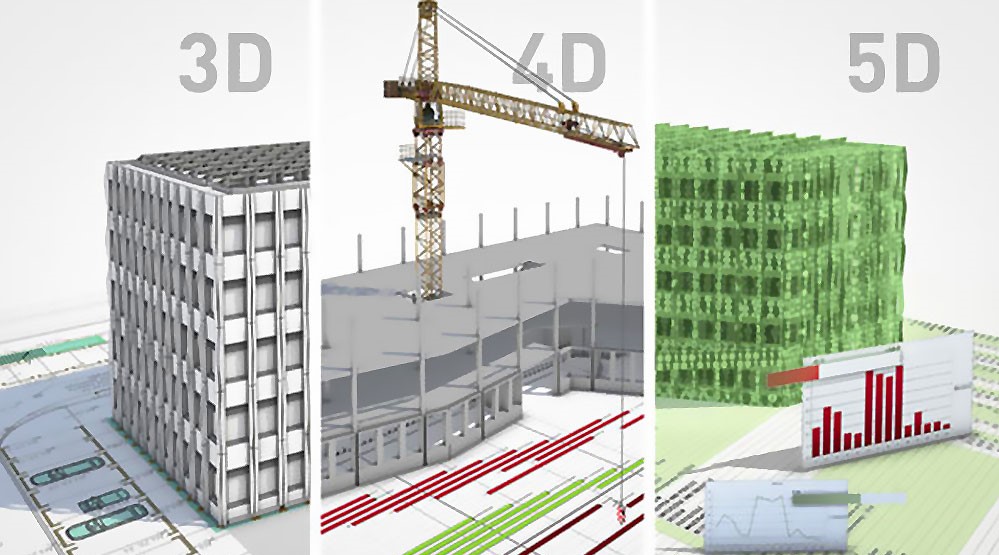

Digital manufacturing helps automate front-end engineering associated with customization. Interactive design for manufacturing (DFM-Design for Manufacturing) tools helps to analyze the design components before manufacturing, which significantly reduces manufacturing risks and enhance productivity. Precisely, these tools improve traceability across the manufacturing process making it more flexible and efficient. Concisely, this digitalization decreases the tooling cost and makes customization economically feasible.

- Improved Product Design and Manufacturing

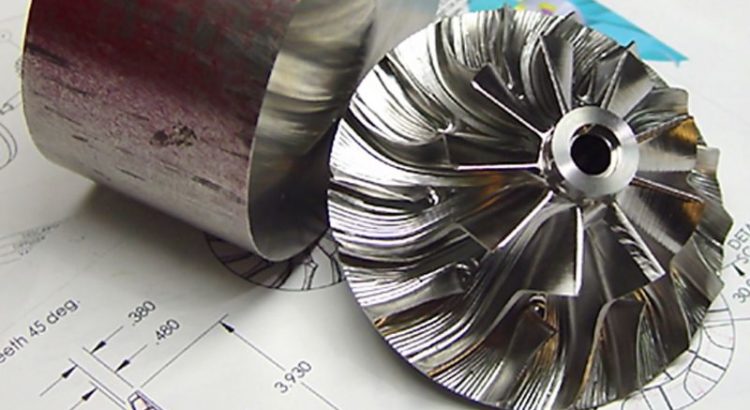

Additive manufacturing is enabling manufacturing organizations to create new and improved products at a lower price. Under the additive manufacturing, engineers have design freedom and assembly reduction, which permits them to customize the product design according to the needs and demands of the industry and customers. Overall, the digital revolution is enhancing product quality, quantity, and variety.

- Low Maintenance Cost and Downtime

Machine learning and AI(Artificial Intelligence) could effectively reduce the maintenance and downtime cost. It is because planned and anticipated maintenance is more efficient compared to maintenance of unplanned problems. So, digital manufacturing helps to anticipate potential risks which eventually reduces the cost incurred due to unexpected events.

- Generating Revenue by Accelerating Production

Digital Manufacturing automates the process of design analysis, toolpathing, and front-end processes. This automation helps in the easy prototyping of product which in turn simplify the supply chain management. With the readily modeled design, manufacturers could enhance the procurement process and subsequently reduce the production time. As a result, the product is launched to the market in time, and high revenues are generated benefitting the manufacturing firm.

Overall, with the digitalization of the manufacturing industry, the labor-intensive work has reduced, and the productivity has increased exponentially. Consequently, the profits have escalated the cost of productivity and maintenance have decreased. All in all, the useful technology innovation in the manufacturing sector have benefitted the overall industry and have paved the way for improved production.