Did you know, the rate of musculoskeletal disorders in the Construction industry is 16% higher as compared to other industries?

These statistics show that construction workers are at significant risk of workplace injuries caused by overexertion and fatigue. However, this risk can be reduced significantly if construction companies adequately harness the potential of technology and automation tools, like the Exoskeleton.

An Exoskeleton comes in handy for lowering stress and strain on construction sites. It is a wearable gadget that resembles a human skeletal structure and has motorized muscles to multiply the wearer’s strength.

Considering the usefulness of Exoskeletons, it can be expected that their popularity likely to grow in the years to come. Researchers predict that by 2025, the market for robotic exoskeletons will grow from $68 million in 2014 to $1.8 billion. Based on these statistics it can be ascertained that Exoskeletons are likely to stay in the times to come. Consequently, the article focuses specifically on disseminating information about the various types of exoskeletons and their applications in the construction sector.

Exoskeletons play an important role in ensuring the safety and efficiency of the construction site. Listed below are some of the many types of Exeskeletons that contribute to reducing construction-induced fatigue and exertion.

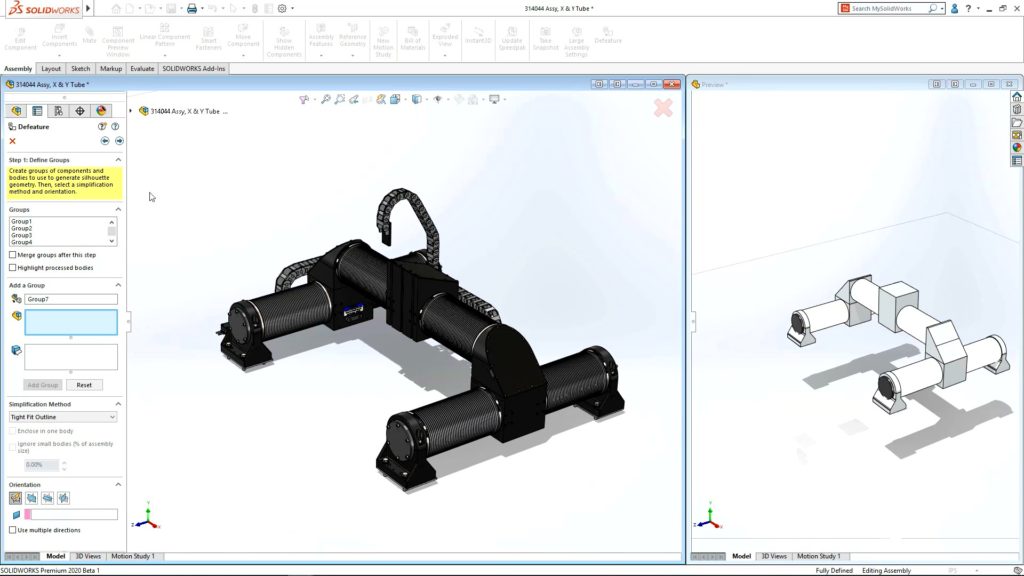

Mounted Arm Exosuit: It is a tool-holding Exoskeleton with a spring-loaded arm connected to a lower-body exoskeleton and a counterweight. It helps workers use hefty hand gears quickly, enabling them to complete jobs faster, with less fatigue, and better workmanship. EskoZeoG and EskoBionics are the commonly used products under this category.

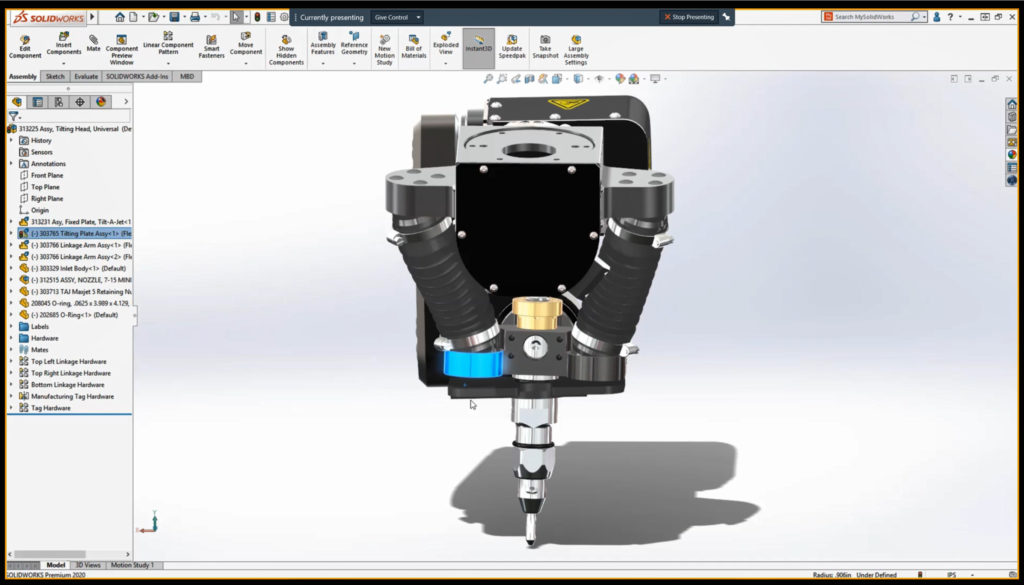

Overhead Exosuit: Workers who perform overhead installation work, such as installing sprinklers or ductwork, benefit from exoskeletons that provide arm, neck, and shoulder support. These gears lessen the strain on the neck and arm muscles and decrease injuries brought on by repetitive stress. Additionally, they offer torso and arm motion without limiting passive or dynamic support.

Power Gloves: For people who have trouble grasping objects or have other dexterity problems, power gloves that fit around the hand can help. When picking up objects or carrying bulky hand tools, the improved grip facilitated by power gloves can be advantageous.

Crouching and Standing Support: A portable exoskeleton called a chairless chair supports workers while they crouch or stand still for long periods. Additionally, they lessen musculoskeletal system diseases and injuries brought on by repetitive stress.

As technology advances, the capabilities of Exoskeletons will further improve, which will eventually contribute to increased workplace safety and higher productivity. Therefore, it is prudent to invest in robotic Exoskeleton technologies to achieve sustainable growth and competitive advantage in the construction industry.