Manufacturers always prefer technologies that promise to make their firms more productive and profitable. One of the most recent concepts is the Internet of Things (IoT) which would revolutionize the industrial design technology. Additionally, use of Augmented Virtual Reality will offer industries to have more vivid experience of the real world. Digitalization is another concept that would give an apparent idea of development and technology dependent world. Further, Artificial Intelligence will become part of our daily life. So, let us briefly understand the Industrial Design Technology Trends in 2019.

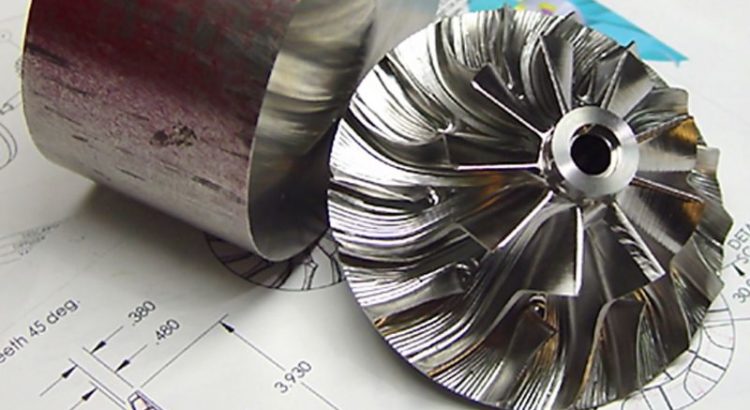

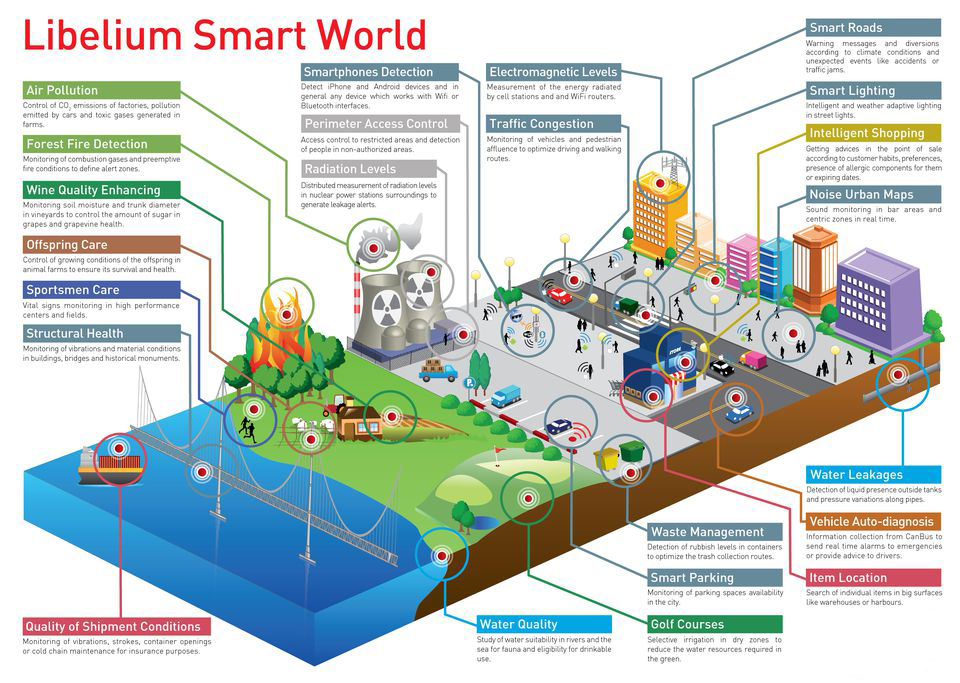

Internet of things (IoT)

Internet of things (IoT)

IoT is defined as a system of interlinked devices. The IoT for industries will empower new ways of ideation, engineering innovation, production execution, and service excellence. It is not just associated with physical objects but also about designing things in virtual space. It will completely change the connectivity power of electronics and software and their interaction. Such products will have the capability to increase the company’s profits as well as deliver significant benefits to consumers.

Augmented Virtual Reality

Augmented Virtual Reality

Augmented Virtual reality is going to change not only what customers do with products but also what they expect from them. It will provide consumers to experience the virtual world more vividly. In the case of designing, designers can pull their ideas out of the screen and can drop it into the real world at full scale. The designers will be able to visualize, interact, and report their findings on product quality from any part of the world. It will surely, advance the design technology and improve industry efficiency.

Digitalization

The use of Digital technologies changes the business model and distribute new income and value-producing chances to business. Digitalization will unquestionably improve the accessibility and will facilitate better information exchange worldwide. A proper digitalization plan will help industries to reinvent processes, improve quality and promote consistency.

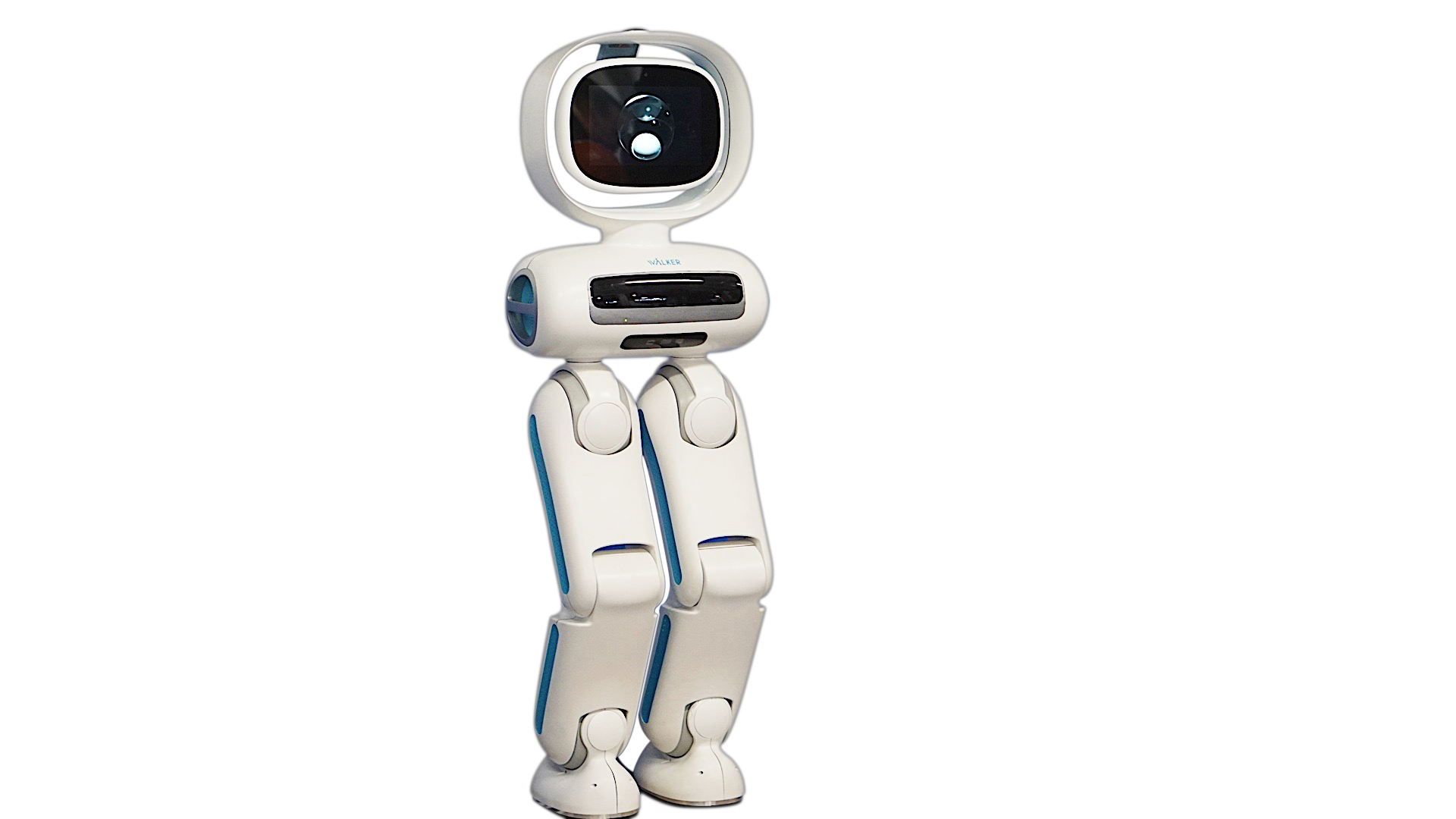

Artificial Intelligence

Artificial Intelligence

Artificial Intelligence (AI) is changing everything, and the Design industry is a part of this change. It is a section of computer science that highlights the creation of intelligent machines which work and respond like humans. Artificial Intelligence Designers will lead multidisciplinary teams in the formation and designing. So, it is very likely that soon AI would take control of the product design domain as well.

Overall, in 2019 many more technologies will evolve which will completely digitalize the design industry and will promote overall organizational growth.