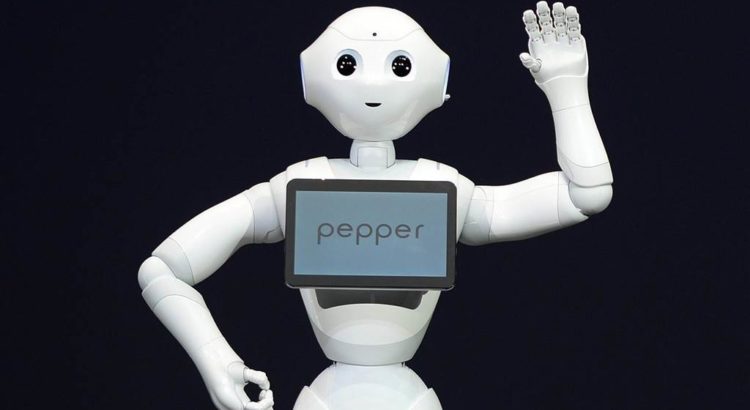

According to the Greek mythology, it is said that we make and imagine our inventions to always look like us. We even imagine an alien or a ghost that look like us. This can be the probable reason why we design robots that look like humans. Technology that is now making the robots intelligent is also teaching them how to be humans. As humans, we try to align our imageries and take inspirations from our environment, which also inspires us to design robots in a humanoid shape.

Many factors may govern our imagination of a human-like robot:

- To impose the same constraints on them, as the world imposes on us.

- The closer the design is to humans, the better it will navigate and manipulate the human world.

- To make them interact with us as we interact with each other.

After being able to design a humanoid, we are still far from the technology that will allow these humanoids to adopt the human abilities completely. If we ever reach such a level of technology, we will give rise to a new species, for whom the human race will simply be like a cannon-fodder in military combat.