ANSYS 19 is also known as the Next Generation Pervasive Engineering Simulation technology. With the expanding digital world and growing data, companies are struggling with the pressure to improve performance to deliver high-quality products within a limited time. ANSYS 19, is designed to empower such engineers and professionals to contribute to the overall productivity. The enhanced capabilities of the technology aim to produce accurate results. Here are some of the many features that will support Pervasive Engineering Simulation.

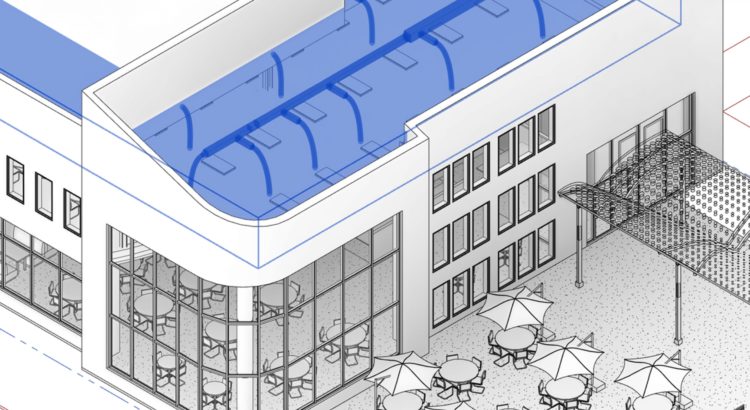

3D Design

ANSYS 19 now introduced the new 3D design family of products.

- The package includes a real-time simulation environment that is developed to help engineers explore their designs and concepts.

- The CAD modeling capabilities of the ANSYS Discovery SpaceClaim now have new assembly configurations.

- Some of its supporting exploded views help engineers generate more efficient designs.

The technology helps to build upon topology optimization so that users can observe live progression to solve steps and make informed decisions.

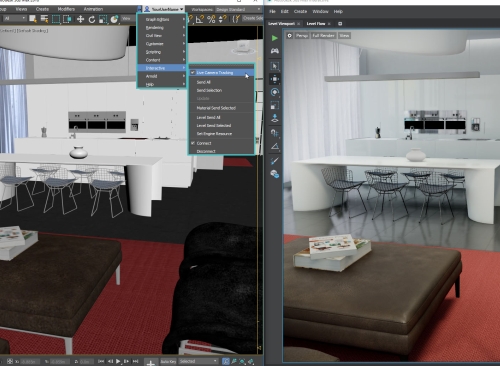

Embedded Software

ANSYS 19 now has powerful capabilities to carry out tasks. These tasks include:

- Workflow integration

- Performance and usability

- A fully certified embedded software with a Human-Machine Interface (HMI) and

- Design capabilities

The technology is also supported by some dedicated solutions for automotive and avionics system and software. Added features here included capabilities for multi-rate application designs and enhanced HMI design capabilities that comply with ARINC 661 and that qualify for ISO 26262 and DO- 178C.

Electromagnetics

With the new technology, engineers can now design wireless, electrification and autonomous technology. The improved features of the technology include radar cross section analysis innovative electronic machine design, integrated electro-thermal analysis, and also a design kit to offer enhanced user experience with all the electromagnetic field simulation tools.

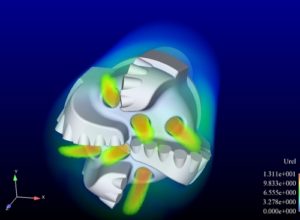

Semiconductors

To meet the growing demands of the next generation computing capabilities, which is not only automotive, but also is mobile, and delivers high performance computing through the advanced system. The technology th us demands products that are bigger, faster, and more complex. The simulation environment offered by ANSYS 19 delivers a platform that is more comprehensive, enabled for Big Data and capable of solving different design attributes such as thermal properties, power noise, performance and reliability across the spectrum accelerating your product success.

us demands products that are bigger, faster, and more complex. The simulation environment offered by ANSYS 19 delivers a platform that is more comprehensive, enabled for Big Data and capable of solving different design attributes such as thermal properties, power noise, performance and reliability across the spectrum accelerating your product success.

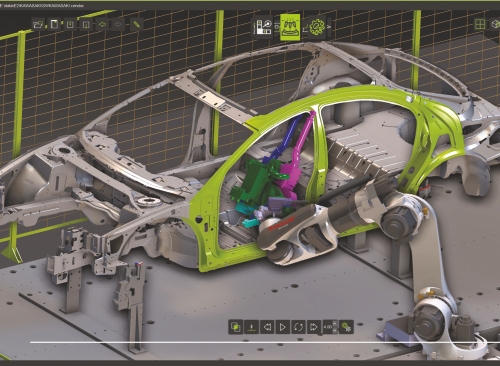

Systems

ANSYS 19 offers some of the most powerful capabilities in two crucial work areas:

- System simulation for battery management design and deployment

- Functional safety and analysis to use across all safety-critical industries

ANSYS 19 now has some enhanced features to help engineers easily model the complete design of a battery management system. Another add-on, ANSYS Simplorer helps the engineers to simulate and test the entire system after design and development. ANSYS 19 expands the functional safety analysis across all industries.