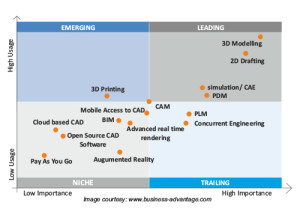

Yes! PTC has successfully launched a new version of parametric CAD software, Creo 5.0. This version of Creo is enticed with new extensions that will bring new functionalities among manufacturing, simulation, augmented reality, topology optimization, and also general productivity improvements.

Here, we have listed new features of the Creo 5.0:

- Additive and Subtractive Manufacturing:

The Creo 5.0 is extending support service of 3D printing with Creo Additive Manufacturing for Materialise allowing users to connect directly to printers for metal printing. Also, the Creo Mold Machining extension is giving high-speed 3-axis and 3+2 positioning machining which is optimized for molds, electrodes, and prototypes.

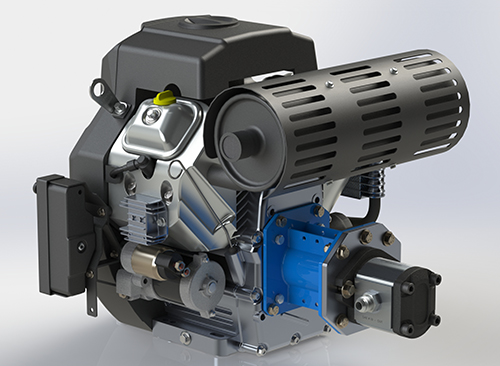

2. Computational Fluid Dynamics:

The new feature of fluid flow extension allows product users or engineers to stimulate the fluid flow directly within Creo. The production company of Creo, PTC also claims that the fluid flow extension is easy to handle, accurate, and brings quick results.

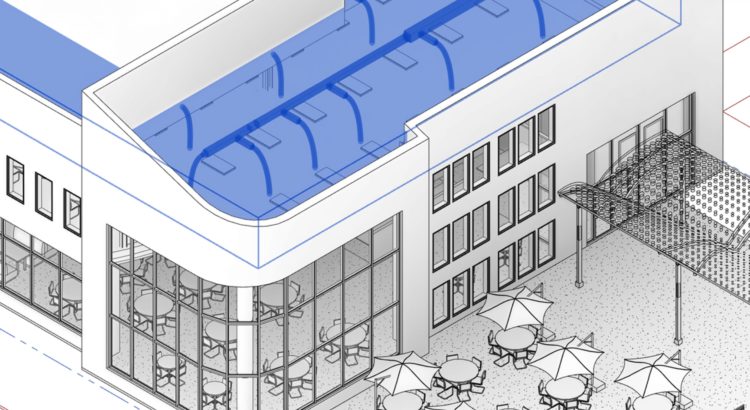

3. BI-Directional CAD:

There is a new collaboration extension which enables the bi-directional exchange of Creo parts and assemblies with the Autodesk Inventor.

- Augmented Reality:

With the development of the new version, PTC integrates Creo with AR platform, by allowing Creo users to manufacture and present AR experience from within the designs.

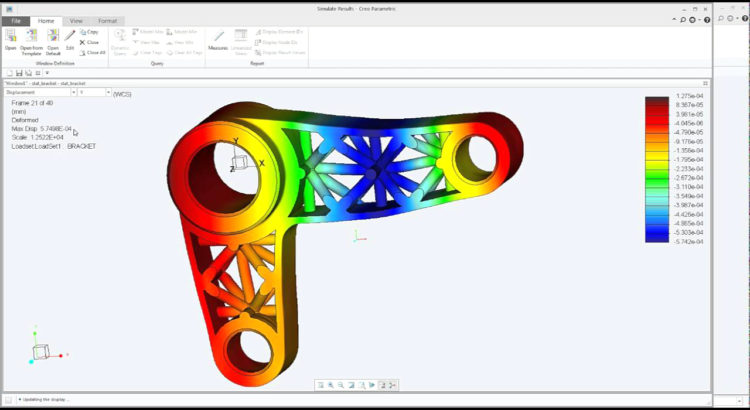

- Topology Optimization:

The feature of topology optimization will enable users to insert objectives and constraints. It will also allow the software to automatically create an optimized design.

- Productivity Improvements:

Creo 5.0 brings some improvements to the productivity of the user, which includes enhanced user interface, geometry creation, volume helical sweeps, design improvements, surface improvements and a lot more. The advancements in this CAD software will result in better functionality and effective product manufacturing.

PTC’s Brian Thompson also said that “Product designs these days requires advancements, and Creo continues evolving to meet the needs of customers.” The changes brought in the product Creo 5.0 reveals that it can help companies right from the earliest phase of design to smart, and useful product.

The significant features of Creo suggests that new functionalities and capabilities, sets the software apart and gives companies a true competitive edge from ideation till manufacturing.