SolidWorks is one of the most popular, widely used, and efficient solid modeling software applications. Over two million engineers and designers all over the globe use SolidWorks as their product design software. The tool is continuously evolving with technology and is covering almost all the aspects of the product development process with a seamless and integrated workflow in design, verification, communication, and data management. SolidWorks is back again with some exciting features in 2019. Here are the top 7 best changes in SolidWorks 2019:

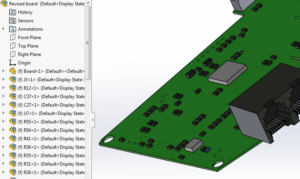

Saving an Asse mbly as a Part: Now designers can save a logical extension of the existing functionality. This feature of the tool will be beneficial in integrating the PCB design. Designers can now save a single board as a manageable component while a product is under development.

mbly as a Part: Now designers can save a logical extension of the existing functionality. This feature of the tool will be beneficial in integrating the PCB design. Designers can now save a single board as a manageable component while a product is under development.

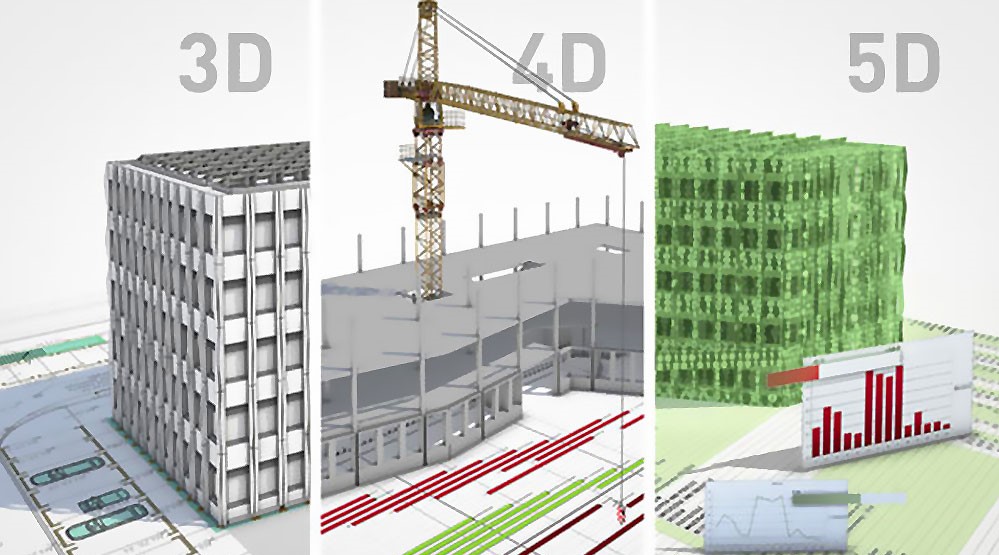

Animat ed Output: An animated output can undoubtedly reveal more details than a picture. The new version allows designers to generate an animated clip for a design under development, offering a better visualization.

ed Output: An animated output can undoubtedly reveal more details than a picture. The new version allows designers to generate an animated clip for a design under development, offering a better visualization.

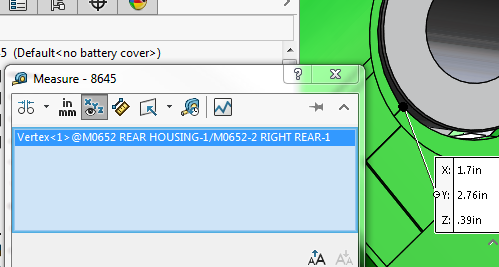

The full time measuring Tool: Designers can now quickly measure designs, which was not possible in the earlier versions. The feature helps to check the changes made, and ensure that they meet the design expectations.

Electrical and PCB: SolidWorks professionals now no longer need separate software to manage PCB designs. SolidWorks 2019, now has integrated functionalities for this purpose allowing designers to work with details in the tool itself.

Deleting Surface Holes: Designers spent a lot of valuable time in activities such as cutting out the rectangular shape, creating the boundary surface and joining the two surfaces together to delete a hole. The new version saves all this time by this feature allowing them to delete a hole directly from the surface.

Product Data Management (PDM):PDM favors multiple user interface, handles complex projects efficiently, and keeps the project consistent and organized; however, it is challenging to implement PDM. SolidWorks 2019 updates make it easy and convenient to work within PDM reducing complexity and enhancing reliability.Simulation: This feature helps developers bounce between the designs and the real models. A detailed view of the product design will help professionals make informed decisions in developing a high-quality product. Simulation in SolidWorks 2019 will also help conduct better tests for the product designs.

SolidWorks 2019 will indeed make life easier for product designers in the future. The improved capabilities will motivate professionals to explore new things and develop better product designs.