Today’s most ground-breaking manufacturing companies are saving thousands of dollars and reducing construction timing by implementing virtual reality (VR). Whether these organizations are designing or authenticating their concepts, or seeing their application in real-time on the construction floor, immersive imagining is proving its worth. Therefore, we have listed below some points to demonstrate the application of VR, check it out:

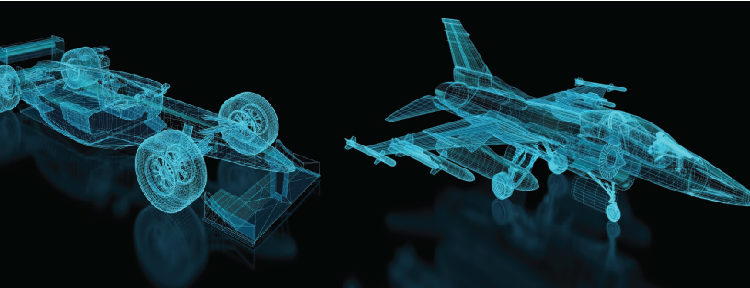

1. CAD-oriented product design

VR is mainly useful to product design teams when they are testing and interrelating with the product.

2. Distinguish in details

Interpreting a virtual product design at a high frame rate is significant for interactive skills that need a lot of movement on the portion of the user. Understanding that there is a catch-22 between assigning resources for geometric difficulty and frame rate.

3. Aesthetics of geometry

Product designs vary importantly, and therefore, significance of aesthetics versus functionality needs to be understood well in advance. High-quality, fully detailed forms are important features that help communicate the aesthetic value.

4. Implementing VR system is not a piece of cake

Though the charge of implementing a VR system for product design continues to go down; however, the financial resources required to build, function and continue it is substantial. Getting people on board internally will be as stimulating as convincing decision-makers in management to pay money.

5. Return on Investments must not depress

Once the VR system is upheld at your organization, track how frequently people are using it, what they are using it for, and why they are using it on database. These records can help you create approximations for potential gains.

Precisely VR system not only helps you design team with advance procedures, but also supports product’s lifecycle. More so, it assists the team understand the ins and outs of installing, working, upholding and fixing a VR system design to produce greater ROI.