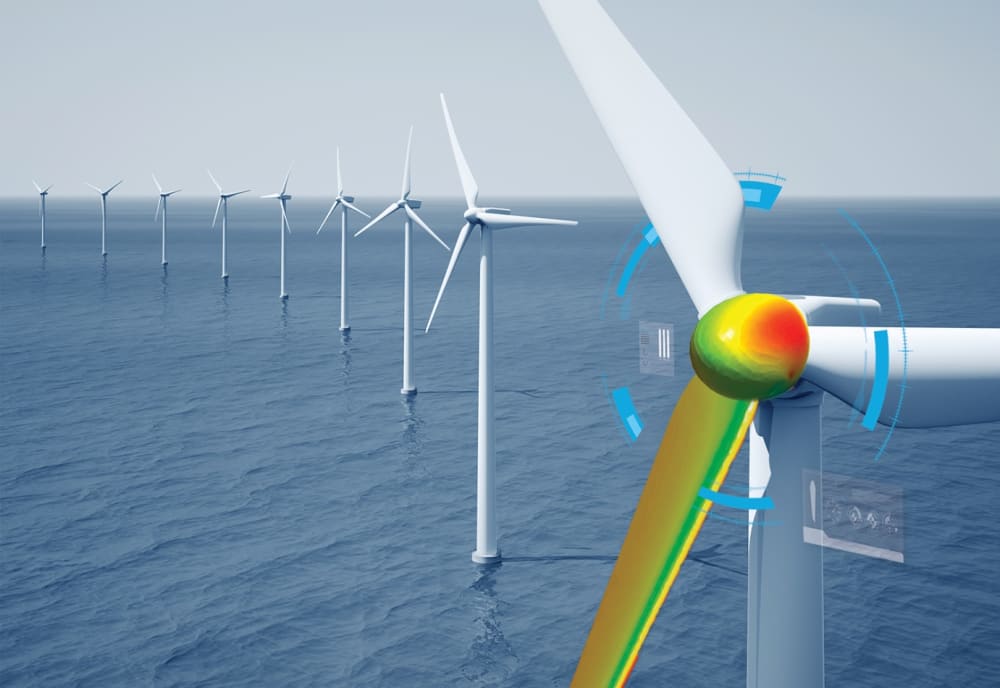

With open source solution integrating Industrial Internet of Things (IIoT) and deploying efficient run-time becomes simple. One such innovation is the ANSYS Twin Builder, which aids in determination of ideal maintenance program, performance optimization, and generation of insightful data to improve products which are next in line through the following features.

Building

In the recent trends, open source technology has come up with a workable solution to overcome the design and building challenges encountered in the field of product engineering. As per the insights of researches it is expected that ANSYS Twin builder will allow the users to go in for multiple modeling which will have domains and languages, extensive 0D application-specific libraries, and third-party tool (including 1D) integration.

This feature, will also allow for reduced 3D order modeling (ROM) creation, product composition through its embedded software integration process and other accurate physics-based twin twice components.

Validation

Initially, building a digital twin was a complicated and challenging process. The ANSYS Twin Builder has changed the above situation and combines everything into a packaged and fluid work flow with intuitive interface features. Through this, users will be able to validate an accurate representation of their real-life products and optimize product performance up to 25 percent by using multidomain simulation with post-processing, rapid human-machine interface (HMI) prototyping, system optimization, and XiL (model-in-the-loop/software-in-the-loop) integration.

Deployment

Through deployment users will be able to quickly connect to supported IIoT platforms and will be able to export/deploy generated models in a timely fashion. Through this, users will be able to improve their operations with a 10 – 20 percent reduction in their maintenance costs.

Compared to the other technological innovation, the ANSYS Twin Builder allows engineers to quickly build, validate and deploy these digital representations of physical products without any hassle. This new trend will also lower the technical and financial costs involved in product maintenance.