Electronics and product design have now become so much inter-dependent that it is difficult to imagine a product that is purely mechanical. Most importantly, the physical form of electronics plays an important role in product design.

Issues with distinct Mechanical and Electronic Design

Mechanical products under development move back and forth between electronics and mechanical design phases during their development life cycle. They also face delays due to reasons such as:

- A board created by the electronic engineer is sent to a third party to create a prototype.

- The prototypes often do not fit into the enclosure due to some additional changes.

- A collective effort of electronic, mechanical, and software engineers also create conflicts.

Uniting Electronic and Mechanical Designs

To resolve such issues, CAD vendors are now making efforts to develop workflows that seamlessly integrate software, mechanical, and electrical parts of product design. For instance, to reduce such delays and improve the overall product development life cycle, Siemens PLM started working with Mentor Graphics in 2017. The product now offers electronics and electrical design with their CAD packages, SolidEdge, and NX.

Similarly, Autodesk is working in association with EAGLE since 2016. EAGLE is Electronic Design Automation (EDA) software that enables the printed circuit board designers to connect easily with schematic diagrams, PCB routing, and component placement.

All of these software vendors strive to create bi-directional associativity without carrying out file translation to develop an easy workflow across electrical, electronic, and mechanical aspects of a product. Designers now enjoy product design benefits such as:

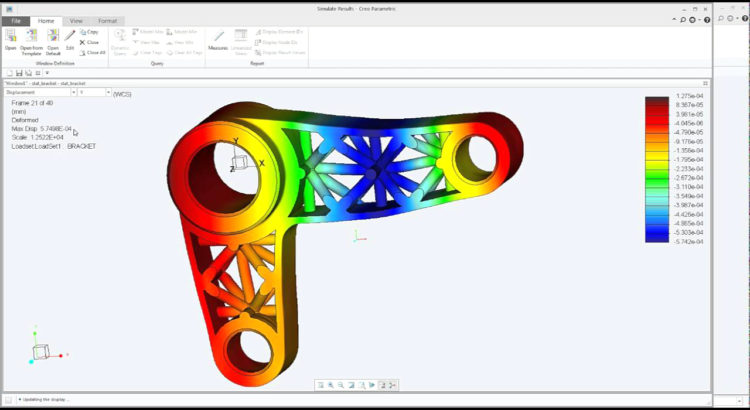

- The integrated suite now supports importing board outlines from the mechanical model design suite Fusion 360 to EAGLE and vice versa.

- The application also letsusers update their component placement on the board.

- It helps to populate each component with a 3D model.

The integrated workflow also faced some constraints in the product design. Typically, the electronics designers have to work under them. Some of these include:

- Size of the board

- Placement of critical components

- Position of the mounting holes

Specialists then developed an integrated EAGLE/Fusion 360 environment which eradicated these issues. Now, any change in one model is directly reflected in another. The best part is, the designer can either choose to accept or reject these changes.

The new functionality has proved to be a game changer in the overall product development and design. Designers can now carry out the product design more efficiently and quickly. The tool also helps the designers to explore new techniques to design electronic products.