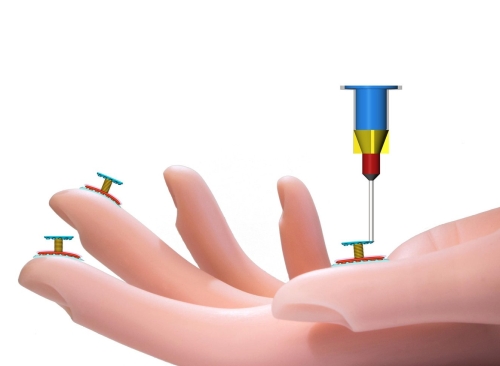

The Engineering researchers at the University of Minnesota have developed a revolutionary process for 3D printing electronic sensory devices that gives robots the ability to feel the environment. The innovation will acts as a significant step for printing electronics on human skin.

Uses of 3D printed Sensors

The lead researcher on the study, Michael McAlpine revealed about the uses of super sensors.

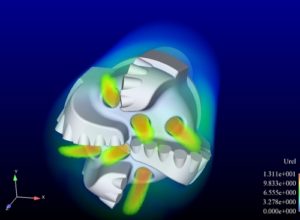

- Introducing bionic skin on surgical robots gives them the ability to make the surgery easier and precise.

- These sensors will make it easier for robots to walk and interact with the environment.

- The innovation will lead to the future sensors that will be printed directly onto the human skin for monitoring their health and protecting soldiers in the field from dangerous chemicals.

- The sensor devices are so sensitive that it can even detect the pulse of an individual.

Designing and Development of Sensors

McApline and his team created a unique sensing fabric with the help of a 3D printer that they built in the lab. The printer is inscribed with four nozzles, which can print with specialized “inks” that forms as layers of the device. All the layers used in flexible sensors can be set at room temperature. Talking about the conventional 3D printing, the researchers said that using liquid plastic is difficult as it is hot and rigid to use on the skin, however; the flexible 3D printed sensors makes the process easy by expanding up to three times the original size.

Going Beyond the Limitations of Biology

In their next experiment, researchers hope to print such “skin” on the human body. Other advancements will include improvement in laparoscopic surgery and provision of touch sensation for the victims. The people who are suffering from prosthetic limbs can gain the touch sense through the artificial skin. Surprisingly, this breakthrough can completely revolutionize mass production.

According to the lead researcher on the study, there can be the arrival of undiscovered applications because the possibilities of future are endless.