Factories today encompass the trending tools like 3D Printing, robotics, laser cutting machines, generative design tools, virtual reality, and augmented reality. All these tools are interconnected and form a network of devices. Now, to operate these highly advanced manufacturing tools, organizations require skilled personnel or the new-collar workforce.

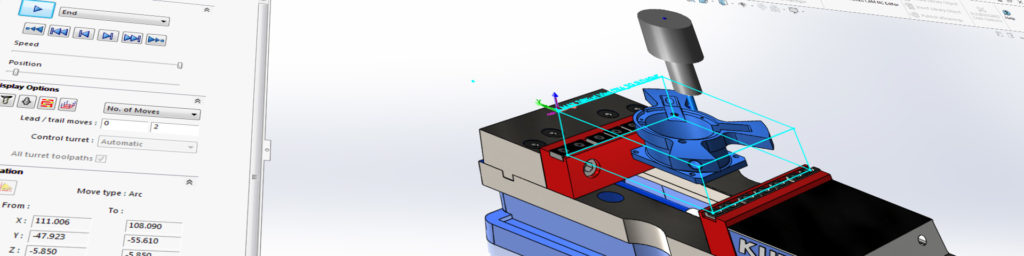

However, manufacturers at present face major skills shortages in their factories as the workforce is incompetent in handling advanced machineries, such as computer numerical control (CNC) machining stations, lasers, automation, and robotics. This large-scale digitalization necessitates workforces with more advanced skills. The skillset of this workforce must include:

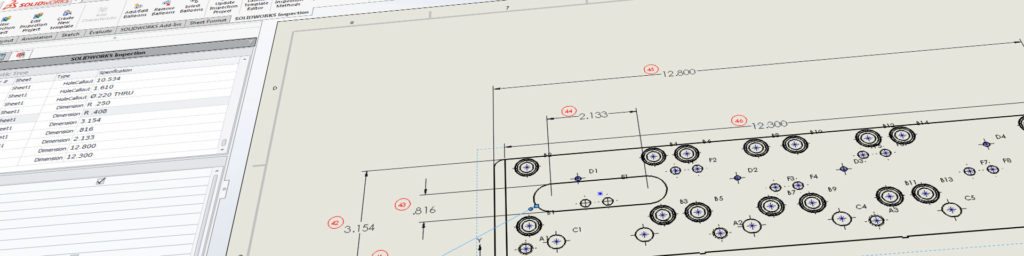

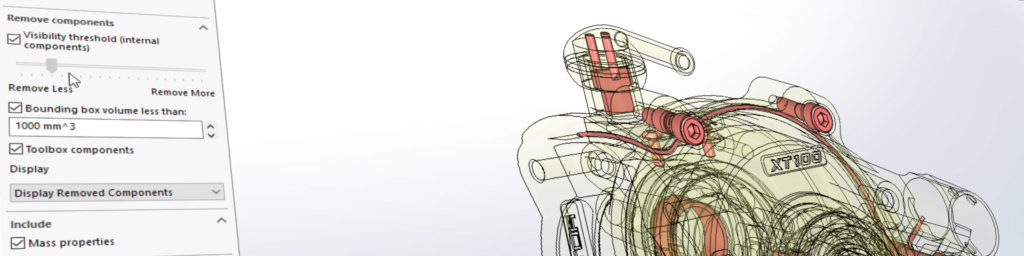

- New collar workers must equip themselves with digital skills which are required for the working and maintenance of software and tools, such as CAD files and programs, 3D printers and robots.

- Manufacturers expect the new collar workers to be skilled in cloud computing maintenance, security analysis and testing, data mining and statistical analysis, data storage management, and user interface operational and maintenance skills.

- New-collar jobs require individuals to possess problem solving, critical thinking, and deep thinking skills to resolve the complex organizational problems with ease.

All in all, if individuals aspire for having a successful career in manufacturing industry, they must acquire the skills for new-collar jobs and accelerate their career growth.