With CAD technology taking over product design and processing in most of the industries, CAD data has become a key component.Security, access and efficient integration of CAD data is one of the primary concerns for industries that use CAD technology for product design and development. Efficient management of CAD data supports a wide range of downstream processes such virtual prototyping, work instructions as well as technical publications.

PDM and PLM are the terms that come into picture when there arrived a need to store and process CAD data when CAD/ CAM was new and the drawings were required to be put somewhere. Storing the CAD/ CAM information was a bit challenge as it was mandatory to put together all the product data at a single location.This laid the seeds for Product data Management (PDM) in the mid 80’s.

Another term that relates to CAD data management is Product Lifecycle Management (PLM).The PLM conceptsdeals with the product entire lifecycle management.It encapsulates the complete process of a product development- right from building the concepts- to prototyping phase- to the manufacturing phase.

Difference between PDM and PLM

PLM can be said as the evolutionary process for Product Data Management (PDM).PDM is a file-based system that is used to manage data for 3D models of physical objects. The PDM system efficiently manages file data and relationships by Creating, Editing or moving them. On the other hand, PLM is a database system for managing products and processes comprising of all disciplines such as Product Management, Product Design, Production, Quality, Marketing, Test Engineering,etc. PLM ensures a complete, approved and locked- down product configuration.

Increased Security and Contro over Products and Processes

All design, engineering, product development, and manufacturing organizations have moved towards an automated solution to manage, utilize and leverage 3D CAD design data in the recent years. And for this,they need both PDM as well as a PLM solution for efficient data management and processing. In fact, all PLM systems use some form of PDM as the underlying data foundation on which they operate.

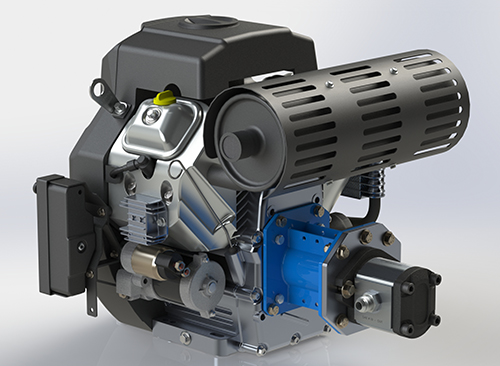

With more and more companies migrating from 2D to 3D CAD systems for their primary product development platform, PDM has grown to become one of the necessities for the manufacturers. The shift of product development through 3D CAD have produced many benefits such as,

• Reduced Cycle Time

• Quality Improvement

• Cost Saving, and

• Accelerated Innovation

Engineers are generating greater volumes of data by becoming more productive with a 3D system. These 3D files contain a varied collection of references, associations, and interrelationships that link them to other files such as operational parts, bills of materials, drawings, assemblies, multiple configurations, documentations, NC Programming, etc.This is thereason the engineers must have a reliable system to manage, preserve and safeguard these files and their respective links.

The use of 3D CAD no doubt increases the volume and complexity of product design data, and requires a capable PDM application to prevent data corruption, file overwriting, loss of data and costly data errors.PDM and PLM systems help product developers automate workflow process boosting the work productivity. This results in faster product time-to-market, shorter development cycles, reduces development costs and an efficient product design.

Efficient Data Processing

For organizations and manufacturers that need to design, produce, source and distribute products around the world, having a single source to manage all the information and processes is essential. PDM and PLM solutions are the way to achieve this. These systems have become a single source of truth to manage all aspects of the product development life cycle.

CAD professionals that work in the manufacturing sector are required to compete globally, push designs intothe market quicker and perform more in a relatively less budget. In this competing economy, where every day and every dollar counts, PDM and PLM tools and technologies have become more valuable than ever.

Collaborative workflow and designs with PLM and PDM shortens R&D cycles, reduces design time, and gives professionals and firms a competitive edge. Some of the key benefits PDM and PLM solutions offer are:

1.Secure Data Management

PDM systems ensure secured data management for the organization.PDM systems efficiently captures and manages product information. This system makes sure that the information is delivered to the users throughout the product lifecycle in the correct context. The PDM systems handle file ownerships, version control, release status and revision management. PDM’s security and administrative functionalities protects intellectual property rights through the project- based security, role management, and associated access privileges.

PDM systems ensure secured data management for the organization.PDM systems efficiently captures and manages product information. This system makes sure that the information is delivered to the users throughout the product lifecycle in the correct context. The PDM systems handle file ownerships, version control, release status and revision management. PDM’s security and administrative functionalities protects intellectual property rights through the project- based security, role management, and associated access privileges.

2. Shorter Time to Market

PLM shortens product development by centralizing control over data. This makes the design teams to work faster accelerating the transfer of design data to production. PLM solutions ensure faster product development and shorter time to market offering a competitive edge for the organizations.

PLM shortens product development by centralizing control over data. This makes the design teams to work faster accelerating the transfer of design data to production. PLM solutions ensure faster product development and shorter time to market offering a competitive edge for the organizations.

3. Drive Innovation

PDM and PLM solutions allow companies that work in CAD to increase their level of innovation without compromising on their flexibility or agility. The product teams are able to work together regardless of their physical location to create the best solutions and final product designs. As there are many CAD tools that are dedicated to developproduct designs, the PLM solutions are making it simpler to achieve industry standards.

PDM and PLM solutions allow companies that work in CAD to increase their level of innovation without compromising on their flexibility or agility. The product teams are able to work together regardless of their physical location to create the best solutions and final product designs. As there are many CAD tools that are dedicated to developproduct designs, the PLM solutions are making it simpler to achieve industry standards.

4. Configuration Management

An efficient PDM system offers the visibility that is necessary to manage and present a complete Bill of Materials (BOM).This facilitates the alignment and synchronization of all the sources of the BOM data with lifecycle phases. These lifecycle visualizations offer sharing and on-demand representations of the product and its underlying assemblies and parts.

5. Increased Productivity

Organizations which do not have PLM system will experience a rapid rise in the industry standards and time efficiencies in product development once it is installed. The PLM systems eradicate time- consuming activities. PLM systems also cut down the processing errors or any associated reworks that arecaused by using outdated technology.

6. Process Enablement

PDM systems help improve workflow and process capabilities.This helps both internal product teams and external partners to participate actively in the product development life cycle. The PDM systems can contributeto establish, manage and execute automated workflow-driven process for CAD tools.

Data Processing with CAD Tools

Efficient 3D CAD tools made manufacturing organizations to shift from 2D to 3D methods of product design and development.The organizations, thus needed an automated solution to manage, utilize and leverage 3D CAD design data. PDM solution, such as the SolidWorks Enterprise PDM has brought a complete change in the PDM paradigm by creating an efficient, easy to use, and affordable solution to meet the PDM needs of any mainstream product design and development organization.

CAD Professionals who benefit from the PDM system include project managers, sales people, engineers, quality assurance teams, and buyers. The PDM system allows companies to:

• Quickly find the correct data

• Reduce cycle time and Improve Productivity

• Reduce Development errors and costs

• Meet business and Regulatory Requirements

• Facilitate collaboration between global teams

• Offer the visibility needed for informed business decision-making

Powerful PDM and PLM capabilities ensures that everyone accesses the correct information, maintaining the correct order and in the correct format. Use of these concepts avoids errors and eliminates unnecessary delays making information accessible anywheresupporting product development.

Image courtesy: www.talisenintl.com // www.linkedin.com //ctmprojectsblog.wordpress.com//