The Simulation tools are making it easier for manufacturers to optimize the process, visualize the entire production path from metal cutting simulations and factory-floor imaging. With the latest tools, the toolpath designers and manufacturing engineers will be able to fix things, speeding the simulation and verification of metal cutting process.

Manufacturers are focusing on ongoing trends for spreading the wealth with higher-end simulation tools throughout the design/production chain.

Sharing CAE with the Masses

From all the latest simulation trends, wider adoption of CAE tools such as topology optimizations, finite element analysis has begun to make way towards manufacturing operations, as engineers outside CAE leverage the power of these simulation technologies. The simulation techniques are applied all across the manufacturing process such as assembly simulation, robotics simulations, human simulations, and ergonomics. Correspondingly, the process of simulation helps in earlier detection of a potential problem, which directly leads to faster processing, increasing tool life, and reduced material cost. Though, the democratization of CAE tools can be experienced for structural analysis, composites manufacturing, and others but, is yet to reach its full potential.

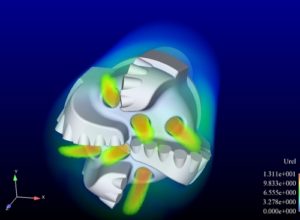

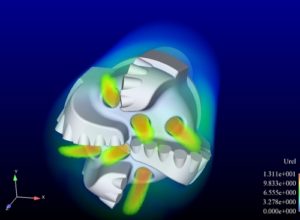

Optimized Drilling

Machine expensi ve corrosion-resistant materials are difficult on drills, to which researchers used fluid flow and structural analysis tools to analyze the coolest fluid distribution and achieve longer tool life. Right from the inclusion of methods to extend the life of drills for the use, a significant amount of heat transported or directing the coolant fluid into small channels. To understand the complex interaction of drill structure, the research team included simulation tools for process optimization by performing fluid-structure interaction analysis. The entire process involved the use of computational fluid dynamics (CFD) and mechanical simulations to modify the cooling process and to improve the tool life by about 50%.

ve corrosion-resistant materials are difficult on drills, to which researchers used fluid flow and structural analysis tools to analyze the coolest fluid distribution and achieve longer tool life. Right from the inclusion of methods to extend the life of drills for the use, a significant amount of heat transported or directing the coolant fluid into small channels. To understand the complex interaction of drill structure, the research team included simulation tools for process optimization by performing fluid-structure interaction analysis. The entire process involved the use of computational fluid dynamics (CFD) and mechanical simulations to modify the cooling process and to improve the tool life by about 50%.

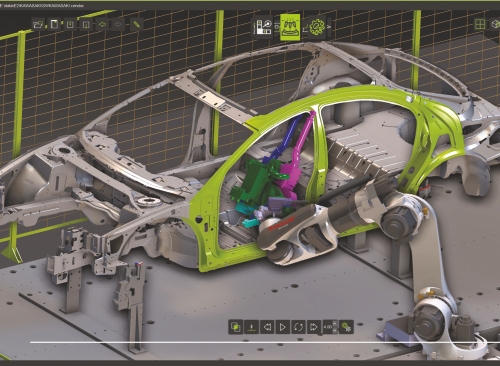

Validating the Digital Factory Drilling

New digital manufacturing simulation tool such as FastSuite Edition 2 enables significant operations, amongst which a few are listed, hereby:

- It helps manufacturers to design factory layout and optimizing product designs.

- It validates manufacturing processes in advance and fastening of the same process and optimizing designs.

- FastSuite also provides user-friendly functions for integrating new and project-specific components in the layout.

- It uses shared memory to write the simulation data and from which 3D visualization then reads the simulation data.

Therefore, the 3D based simulation software allows validation and visualization of processes and production tasks.

In the end, the involvement of simulation tools can handle customized markets, making of adjustable product structure, and complexity of big orders.