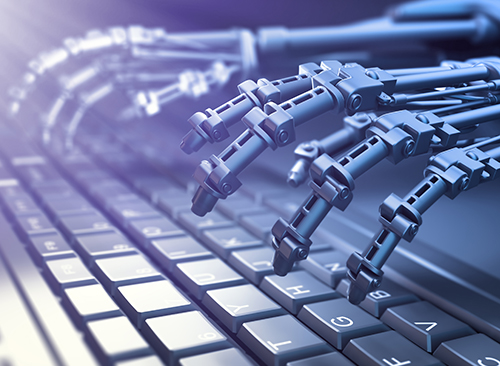

Are computers killing jobs? Yes, they are! On the other hand, they also are creating a complete new area of job opportunities for the technical people. No doubt, the modern machines, and Artificial Intelligence have today made manual and paperwork disappear. And this trend is expected to rise in the next five years threatening many jobs in the market.

So where are the opportunities then? Well, the rapid increment in the Information and Technology sector has opened many profiles on the technical front. Artificial intelligence, nanotechnology, and many other specialized fields today need skilled and well-qualified personnel to compete in the market.

This boom in the technology also challenged many Government employees working across organizations. And as a result, they were provided additional training and mentoring to be competitive in the rapidly changing market.

Owing to this approach in the employment, it is also estimated that children entering in the primary schools will work across profiles that no longer exist today. This revolution indicates a clear picture that this rapidly changing technology will indeed create unimaginable areas of careers and job profiles in the future.

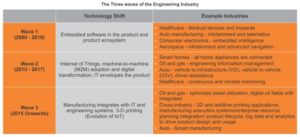

Smart Engineering Killing Technical Jobs

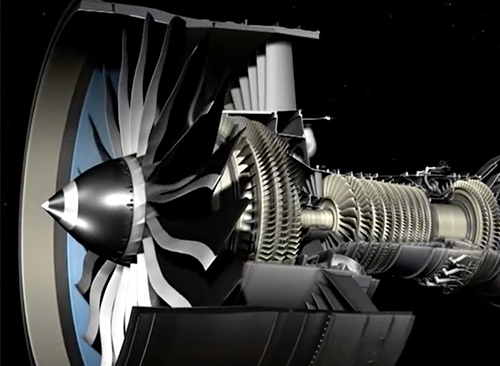

Better machines have undoubtedly replaced jobs that involved risks in the technical field. Many industries are now using automated methods in the product or service processing, manufacturing and distribution too. These are the areas where technical people, mostly the engineers were working since ages. Although the introduction of advanced and hi-tech machines and intelligent algorithms have increased productivity and efficiency two-fold, it has also grabbed many jobs and profiles of people working in this discipline.

Technologies such as Artificial intelligence, Sustainable Production, 3D Printing, Robotics, and resource efficient techniques have introduced new ways and means to develop better products and services in this field. This technology also opened gates to a complete new area of job profiles across these fields.

So, what these industries really need? Keeping in mind the drifting work profiles, professionals now need to have strong communication skills, rather than, only the technical skills. Skills that can help them to coordinate best among each other – skills enough to dig deep to find out future possibilities with the technology, and open-mindedness to readily accept and appreciate innovations with an open mind.

Robots made HealthCare easy!

Robots made HealthCare easy!

Diagnosing diseases at an early stage and effective medication have saved several lives. Hi-tech machines and computer-driven robots have made complex surgeries simpler to use. Doctors are today not only specialists in their own fields but are also pros at using these smart machines. Technology has made surgeries possible even from remote locations and provides instant relief to the patients irrespective of their location.

So are the doctors, tech people too? The answer is apparently yes! As technology spreads its wings in the healthcare sector, now doctors are trained to operate these smart machines. This integration of technology and medicine has changed the way a patient is treated today.

And this shift of healthcare service made it necessary for the healthcare professionals to get trained to operate these computer driven machines. This trend now needs the doctors to not only have knowledge about healthcare but also to work with these machines.

The introduction of technology thus made it necessary for them to get trained to use them to match the changing trends in this sector.

Skills the Fourth Industrial Revolution Demands

The Fourth Industrial Revolution is expected to bring change in the professional lives of many people. People that possess multiple skills- not only technical but also mathematical and social will rise in their career.

On the other hand, people that possess single skill set may have to face many challenges in the market. This theory not only applies in the field of engineering or medicine but also across fields of business as well as agriculture.

With such a shift in the workflow, many experts argue that now with technical empowerment, social skills of negotiating and sharing will be crucial. Skills that we learn at the pre-schools will be valued highly as with technology doing most of the technical skills; people may have to move across projects and roles.

Soft skills that encourages employees to coordinate, cooperate and support one another across tasks will be crucial. Along with these, the mathematical and statistical ability will also be hugely beneficial.

So where do we need to Focus?

To match and sustain our position in the market, and also to accelerate in our careers, it is apparently clear that we need to bring change in the education system in schools and colleges. Candidates need to get trained today in both technical as well as social skills in order to cope up with the industry needs.

Anticipating the change in the market trends and the rise of technology, researchers now believe that jobs that required single skill sets will no longer exist in the future. To match the market needs and the changing business operations, students now should be encouraged to develop social skills, similar to that are taught at the primary schools. Business should learn the areas of development of their own activities and should be openly willing to share and contribute each other to develop.

These soft skills are also important because they help you reach new opportunities at workplace along with the current ones. These skills help you to improve your overall personality- attitude, work ethic, communication skills, emotional intelligence, personal attributes and the way you deal with different people.

These social and interpersonal skills have now become important as they play a crucial role in the success of a professional making them more productive and efficient. It has therefore become necessary for the students in the college and schools to be exposed to such soft skills.

Apart from mathematics, statistics, computer science, engineering, agriculture, or any other workplace, they also need soft skills to work together, share and negotiate empowering them to compete in the new job markets.

Image courtesy: www.cdn-images-1.medium.com || www.icomoney.com ||

www.17026-presscdn-0-98.pagely.netdna-cdn.com ||

www.osuwmcdigital.osu.edu || www.cdn.mos.cms.futurecdn.net/

www.greenblog.jll.com ||