Technology has grown up to a large extent in the recent past years. It showed some of the technical marvels that were never imagined before. One of them was the evolution of the 3D printing technology that made it possible to transform computer models into real world objects.

Ever since the dawn of 3D printing, it never left the sky. The technology first started printing with metal alloys and plastic materials. Growth never stopped and now a number of other materials have been used to produce 3D printed objects. Technology made it possible to use a different “inks” that made it possible even to print living cells and semiconductor batteries.

3D printing soon entered the micro scale device manufacturing. Experts, scientists and researchers from the top organizations such as University of Harvard, Cambridge, Princeton, UCLA, and Minnesota have been constantly working on this 3D printing technology and soon came up with designing micro scale devices and gadgets that were even smaller than the width of a human hair.

On the way forward, material science experts and Biologists worked together to take things on a complete new level.

- They developed objects that hold properties of both- life science and electronics.

- Materials with multivariate characteristics of materials were developed that can be potentially used as a fluid in micro-scale printing.

- On the same way, scientists from the University of Princeton developed a fully functional bionic ear blending biology and electronics together.

The Next Step- 4D Printing

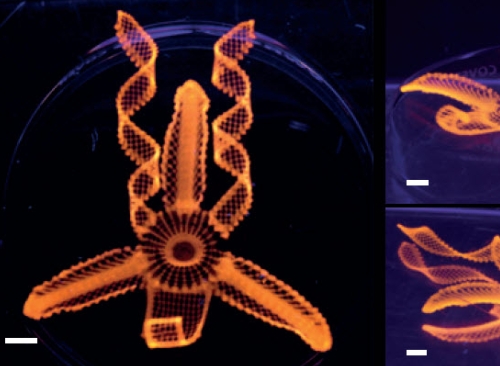

Professor Lewis, a researcher from the Harvard University has been working on this technology in her Lewis lab from a while. She has been showing a keen interest on developing 3D printed objects that had features as small as one micrometer. The Lewis lab again gained recognition when they developed objects that actively responded to external stimuli.

Inspired by many plants that responds by the external stimuli, this 4D technology was a big breakthrough.

- The 4D-printed hydrogel composite structure changed shapes when immersed in water.

- Objects now started moving in the fourth dimension when we were only brainstorming around the third one.

- Combining both biological as well as electronic properties, researchers soon developed micro scale structures.

- 4D printing soon made objects change into any arbitrary shape using any suitable material.

This 4D printing technology is said to be competent enough to print dynamic micro scale structures that can significantly contribute in both industrial as well as medical domains.